First Stage TechnologyHomeDiving TechnologyFirst Stage TechnologyBalanced Piston

FIRST STAGES

The task of a first stage regulator is quite simple: reduce high

pressure air coming from the tank to a consistent intermediate

pressure. They are generally divided into PISTON and DIAPHRAGM

categories, depending on the mechanism used to control the valve,

allowing air to flow to the second stage. Due to their design and

their particular advantages, each of them have become the favorites

of different groups in the diving community. First stages can be

further classified between CLASSIC DOWNSTREAM and BALANCED,

affecting function and performance of the first stage related to

pressure changes in the tank.

THE PISTON TECHNOLOGY

The general advantage of a piston-based first stage lies

in its reliability and reduced maintenance requirements, due to an

effective but simpler mechanism with less moving parts. More

importantly, no other design can reach the high air delivery rate

of a balanced piston controlled first stage.

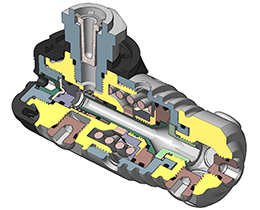

Air balanced flow-through piston

First stages with air balanced pistons deliver

significantly more air to the second stage than any other first

stage, while their performance is totally unaffected by the

changing tank pressure. A balanced piston allows the use of lighter

and more sensitive components, resulting in ultra fast breathing

response, instant delivery of air on demand and extra high air

flow, especially in low tank pressure ranges. The tired diver

benefits from of a smoother breathing regulator during the ascent

or deco stop. Balanced piston first stages are the first choice of

demanding sport divers and professionals. A balanced piston

performs equally in both warm and cold water environments. The

SCUBAPRO MK25 first stage uses this

technology.

Air balanced flow-through piston details

Classic downstream piston

This is the best example of bulletproof reliability and

trouble-free, minimal maintenance regulators. The conventional

downstream piston confi guration is the simplest mechanism that

exists to control the pressure drop from a tank to feed the 2nd

stage. The classic downstream valve is the first choice of diving

centers and rental facilities worldwide for warm and moderate water

temperatures. Our MK2 Plus features this

technology.

THE DIAPHRAGM TECHNOLOGY

Diaphragm-based first stages are environmentally

sealed so that water cannot enter the inner mechanism. Bearing in

mind that regulators generate temperatures up to minus 30 °C

due to the incredibly fast moving air and the high pressures

involved, it is imperative that sensitive moving metal parts avoid

contact with extremely cold water.

Therefore, diaphragm first stages have been the favored choice of

cold-water divers and those working in contaminated or muddy

water.

All our diaphragm first stages feature a balanced technology and

are packed with patented features resulting in ultra fast flow to

the second stage upon request and a fantastic overall

performance.

The balanced diaphragm technology provides

consistent performance at all cylinder pressures, at any depth

and optimises the second stage performance, thus allowing for

effortless breathing.

Our MK17 diaphragm first stage features a dry balancing chamber so that the water cannot enter the first stage, this means it's resistance to freezing is unmatched even in extremely cold waters.

Balanced diaphragm with dry chamber details

Our MK11 diaphragm first stage has the same structure as MK17 but without a dry chamber and it is the perfect choice for the recreational diver who wants the advantage of a diaphragm fisrt stage for use in temperate waters.